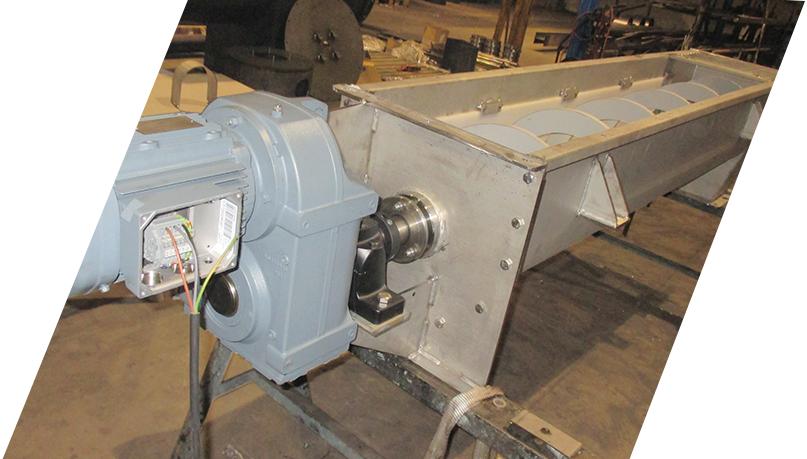

Shaftless Bed Conveyors (TRF)

HELI – TRANS

Manufacturers of bed conveyors with a U-shaped housing

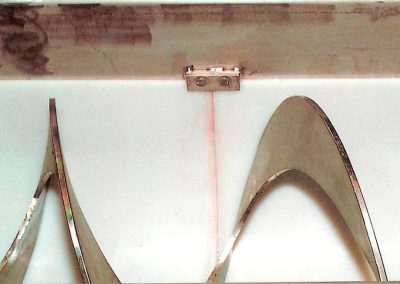

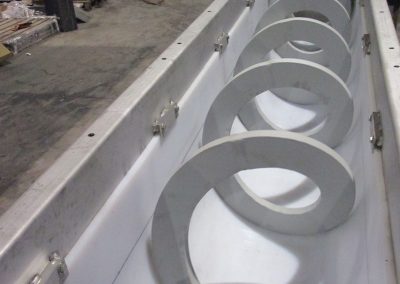

Our shaftless bed conveyors (TRF) are systems with a U-shaped housing and screwed-on covers in which the auger is shaftless and has an increased thickness.

The ideal solution: shaftless bed conveyors

Shaftless bed conveyors are the ideal solution for moving sludge and solid waste in wastewater treatment plants, sticky or fibrous materials, pulp or paper, as well as irregularly shaped solids such as wood chips.

Their use is also common in slaughterhouses, meat waste companies, and water treatment plants, as the closed design prevents product losses and the emission of bad odors.

Simple shaftless bed conveyor design

The equipment can be manufactured in carbon steel, stainless steel, or mixed steel options, seeking to obtain a balance between the price and the installation’s requirements.

For pieces of equipment that have to transport more abrasive products, is also possible to install the bed in anti-wear steel — either directly in the same way as the bottom liner for the trough or by means of longitudinal plates.

Shaftless bed conveyor safety

As safety and control measures, the installation of rotation detection systems, fill detection systems, and even electromagnets for the removal of metals can be requested.

As Heli-Trans is a direct manufacturer of augers and conveyors, we can adapt the design and the inlet and outlet points to the needs of our customers. We can likewise replace the parts that make up the equipment by simply indicating the machine model number and the description of the part required.

For custom-supplied parts that will sustain wear, we recommend purchasing the spare part when purchasing the equipment, thus reducing costs and ensuring rapid maintenance.

our providers

Need help?